Understanding the Basic Refrigeration Cycle

Published on: October 23, 2024 | By Supaload

Introduction

The refrigeration cycle is essentially a heat transfer system. Its job is simple: move heat from inside your cold room to the outside environment. The refrigerant is just the medium that carries this heat from one place to another. Think of it like a delivery system - the refrigerant picks up heat from where you don't want it (cold room) and delivers it to where it doesn't matter (outside air).

📚 Further Reading:

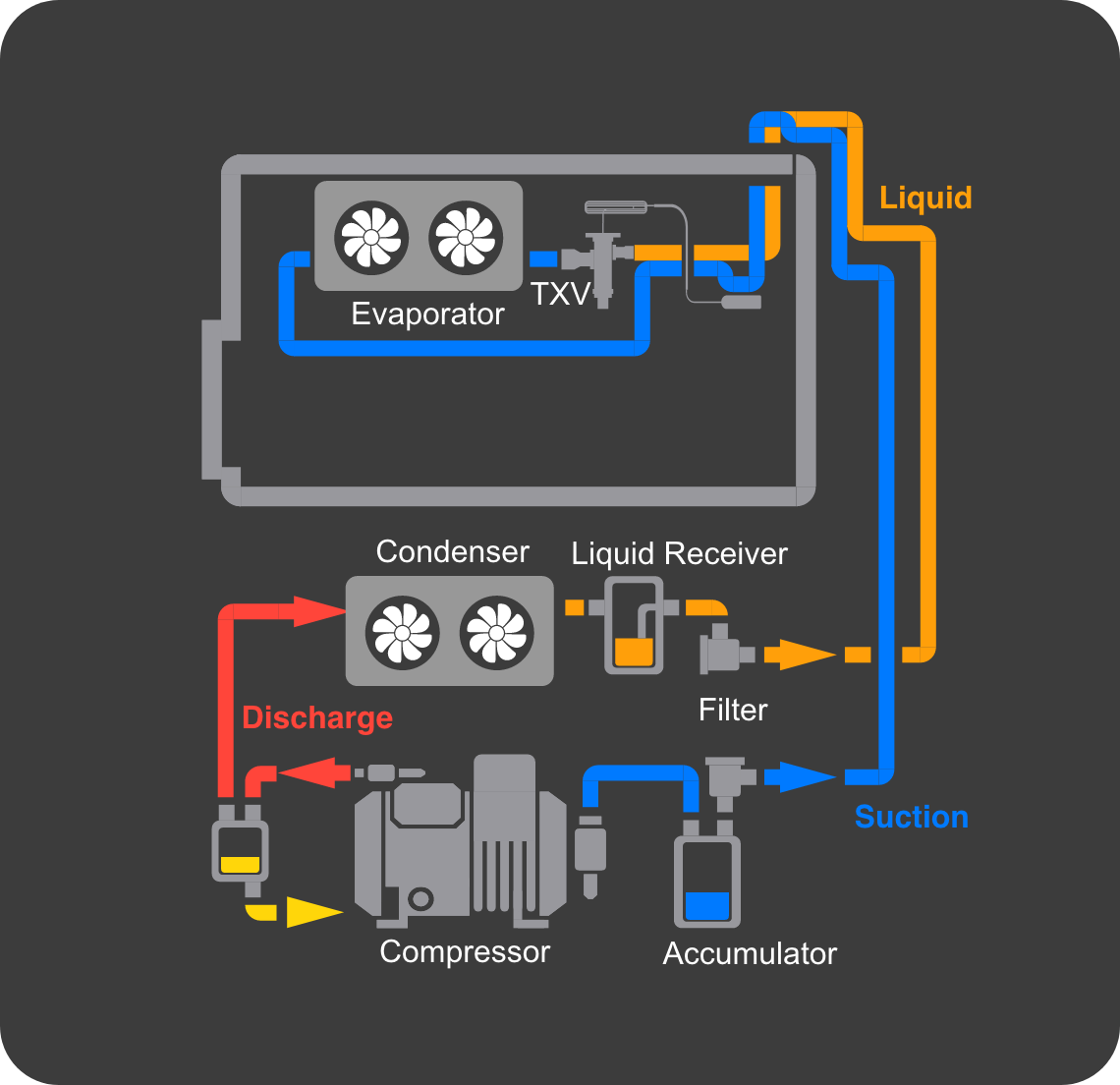

Visual Demonstration

Watch this video to see the complete refrigeration cycle in action. Notice how the refrigerant flows through different colors representing different stages of the heat transfer process:

Video Description

This video shows the complete heat transfer process, with refrigerant moving heat from the cold room to the outside environment using the color-coded flow system.

The Basic Concept: Heat Transfer

At its core, refrigeration is about moving heat. The system doesn't create cold - it removes heat. When heat is removed from a space, that space becomes colder. The refrigerant circulates through the system, picking up heat in one location and releasing it in another.

Heat Pickup Point

The evaporator (inside the cold room) is where the refrigerant picks up heat from the air, making the room colder.

Heat Release Point

The condenser (outside) is where the refrigerant releases the heat to the ambient air, warming the outside environment.

Continuous Process

This heat transfer happens continuously, maintaining the desired temperature in your cold room.

The Water Spray Analogy

To understand how refrigeration works, imagine a water spray bottle with a fan. When you spray water on your hand and then turn on a fan, the water droplets absorb heat from your skin, making your hand feel cooler. The fan blows air over the water, making it evaporate much faster. As the water absorbs heat and evaporates, it turns into vapor. This is exactly how the refrigeration cycle works!

Water Spray = Expansion Valve

The expansion valve is like the nozzle of a spray bottle. It sprays the refrigerant liquid, creating tiny droplets with large surface area.

Your Hand = Cold Room

The cold room is like your hand - it's where we want to remove heat to make it cooler.

Fan = Evaporator Fan

The evaporator fan is like the fan blowing air over your hand. It circulates air over the cold refrigerant, making heat transfer much faster and more efficient.

Water Droplets = Refrigerant

The refrigerant is like the water - it absorbs heat and then evaporates into vapor, especially when air is blown over it.

1. Evaporator - Where Cooling Happens (Heat Pickup Point)

The evaporator is where the magic happens - this is where your cold room actually gets cooled. Think of it like spraying water on your hand and then turning on a fan to make it evaporate faster.

The Spray Process

High-pressure liquid refrigerant flows through the expansion valve (like water through a spray nozzle). The pressure drops dramatically, and the refrigerant becomes very cold (typically -30°C to -10°C / -22°F to 14°F).

Fan Circulation

The evaporator fan circulates air over the cold refrigerant (like a fan blowing over water on your hand). This makes heat transfer much faster and more efficient, just like how a fan makes water evaporate faster from your skin.

Heat Absorption

The cold refrigerant droplets absorb heat from the cold room air (like water droplets absorbing heat from your hand). As it absorbs heat, the refrigerant temperature rises to typically -5°C to +10°C (23-50°F).

Evaporation

Just like water evaporates faster from your hand when a fan is blowing, the refrigerant evaporates more efficiently as air circulates over it. It changes from liquid to vapor, which is why this component is called the 'evaporator'!

2. Compressor - The Heat Mover

The compressor is like the engine that moves the heat from your cold room to the outside. It takes the cool refrigerant vapor that has absorbed heat from the cold room and compresses it. During compression, the compressor itself generates heat from the mechanical work, and this heat is also absorbed by the refrigerant, making it even hotter.

Heat Transfer Function

The compressor's job is to move heat from the cold room to the condenser, where heat gets released to the outside air. The refrigerant is simply the medium that carries this heat.

Compression Process

The compressor squeezes the cool refrigerant vapor (typically -5°C to +10°C / 23-50°F) into hot vapor (typically 60-90°C / 140-194°F), increasing pressure significantly (varies by refrigerant type and design conditions).

Heat Generation

During compression, the compressor generates heat from mechanical work (like friction and motor heat). This heat is absorbed by the refrigerant, contributing to the temperature increase from cool vapor to hot vapor.

Continuous Operation

The compressor keeps running, continuously moving heat from inside to outside, maintaining the cold room temperature.

3. Condenser - Heat Release Point

The condenser is where the heat gets released to the outside environment. Think of it like breathing on a cold window - your hot breath hits the cold glass and forms water droplets. The hot refrigerant vapor from the compressor flows into the condenser and releases its heat to the ambient air, changing from vapor back to liquid.

Breath on Cold Window Analogy

Imagine breathing on a cold window. Your hot breath (like hot refrigerant vapor from compressor) hits the cold glass (like ambient air) and forms water droplets (like refrigerant liquid). The condenser works exactly the same way - hot refrigerant vapor releases heat to the cooler outside air and condenses back to liquid.

Condenser Fan

The condenser fan circulates air over the hot refrigerant (like a fan blowing over your breath on the window). This makes heat release and condensation much faster and more efficient, just like how air movement helps water droplets form faster on the cold glass.

Heat Release Process

The hot refrigerant releases heat to the outside air, cooling down from typically 60-90°C (140-194°F) to 35-50°C (95-122°F).

Phase Change

As the refrigerant cools, it changes from hot vapor back to warm liquid, just like hot breath condensing into water droplets on a cold window. This liquid is ready to go back and absorb more heat from the cold room.

4. Supporting Components

Several components help the system run smoothly and efficiently.

Liquid Receiver

Stores the cooled liquid refrigerant and ensures steady supply to the system, like a water tank for the spray bottle.

Liquid Filter & Suction Filter

Removes contaminants and moisture from the refrigerant, keeping the system clean and preventing damage to components.

Suction Accumulator

Ensures only vapor reaches the compressor, preventing liquid refrigerant from damaging the compressor.

Oil Return Line

Keeps the compressor properly lubricated for smooth operation.

5. Back to Evaporator - Completing the Cycle

The condensed liquid refrigerant from the condenser now flows back to the evaporator through the liquid receiver and filter. When it reaches the expansion valve, it gets sprayed again (like water through a spray nozzle), becoming cold and ready to absorb more heat from the cold room. The cycle continues continuously, keeping your cold room at the desired temperature.

Liquid Flow Back

The warm liquid refrigerant (typically 35-50°C / 95-122°F) flows from the condenser back to the evaporator through the liquid receiver and filter, ready to be expanded again.

Expansion Process

The expansion valve sprays the liquid refrigerant, reducing its pressure and temperature dramatically (typically -30°C to -10°C / -22°F to 14°F), making it cold enough to absorb heat from the cold room.

Continuous Cycle

This process repeats continuously: liquid gets sprayed → absorbs heat → becomes vapor → gets compressed → releases heat → condenses back to liquid → flows back to be sprayed again.

Refrigerant Flow and Color Coding

To help you understand how the refrigerant moves heat through the system, we use color coding in our visual demonstration. Each color represents a different stage of the heat transfer process.

🔴 Discharge Line

This is the 'hot delivery' line. The refrigerant here is carrying heat from the cold room to the condenser. It's hot (typically 60-90°C / 140-194°F) and under high pressure (varies by refrigerant type and design conditions) because it's loaded with heat energy.

🟠 Liquid Line

This is the 'ready to cool' line. The refrigerant has released its heat in the condenser and is now a liquid, ready to go back and pick up more heat from the cold room. It's still under pressure but much cooler (typically 35-50°C / 95-122°F).

🔵 Suction Line

This is the 'heat pickup' line. The refrigerant has absorbed heat from the cold room and is now a cool vapor (typically -5°C to +10°C / 23-50°F) under low pressure, ready to be compressed and sent to release its heat.

🟡 Oil Return Line

This line ensures the compressor stays properly lubricated. It returns oil from the oil separator back to the compressor, keeping the system running smoothly.

Key Takeaways

The refrigeration cycle works like a water spray system: refrigerant gets sprayed (expanded), absorbs heat from the cold room, evaporates into vapor, gets compressed to release heat outside, condenses back to liquid, and repeats the cycle continuously.

🔴 Heat Delivery (Red)

Compressor → Condenser. Hot refrigerant (typically 60-90°C / 140-194°F) carries heat to be released outside.

🟠 Ready to Cool (Orange)

Condenser → Expansion Valve. Cooled liquid refrigerant (typically 35-50°C / 95-122°F) ready to be sprayed and absorb heat.

🔵 Heat Pickup (Blue)

Evaporator → Compressor. Cool refrigerant vapor (typically -5°C to +10°C / 23-50°F) that has absorbed heat from the cold room.

🟡 System Maintenance (Yellow)

Oil return line ensures proper compressor lubrication for continuous operation.

Related Articles

BTU Calculator for Cold Room Refrigeration

June 12, 2025

Learn how to use a BTU calculator to accurately size commercial refrigeration equipment by accounting for wall heat gain, air change load, and product loads.

Software vs Manual BTU Calculations: Which is Better?

June 15, 2025

Compare software-based and manual BTU calculation methods for refrigeration projects. Learn the pros and cons of each approach.

Designing Cold Rooms with 100% Redundancy and Dual Evaporators

October 21, 2024

Learn how to design a cold room with 100% redundancy using dual evaporators. Explore design options and best practices.